After struggling to extract some flavours out of some pretty good coffees, i decided it was time to move on from my temperature surfing technique to something more reliable and repeatable. After convincing my fiancée about the idea, i went ahead and ordered a PID controller for the Silvia from Auber. I’ve received the package (from US to Europe) in three working days, which was surprisingly fast. The installation itself took about 1-2 hours as i absolutely didn’t want to rush with it. Auber has also provided a PDF with instructions.

The kit definitely looks better than i expected and feels great – very solid with a high quality built. The display is white and bright, the system itself is easy to navigate. The improvement is significantly noticeable.

Disclaimer : What you're about to read isn't science, but rather my observations and informations based on my personal research only.

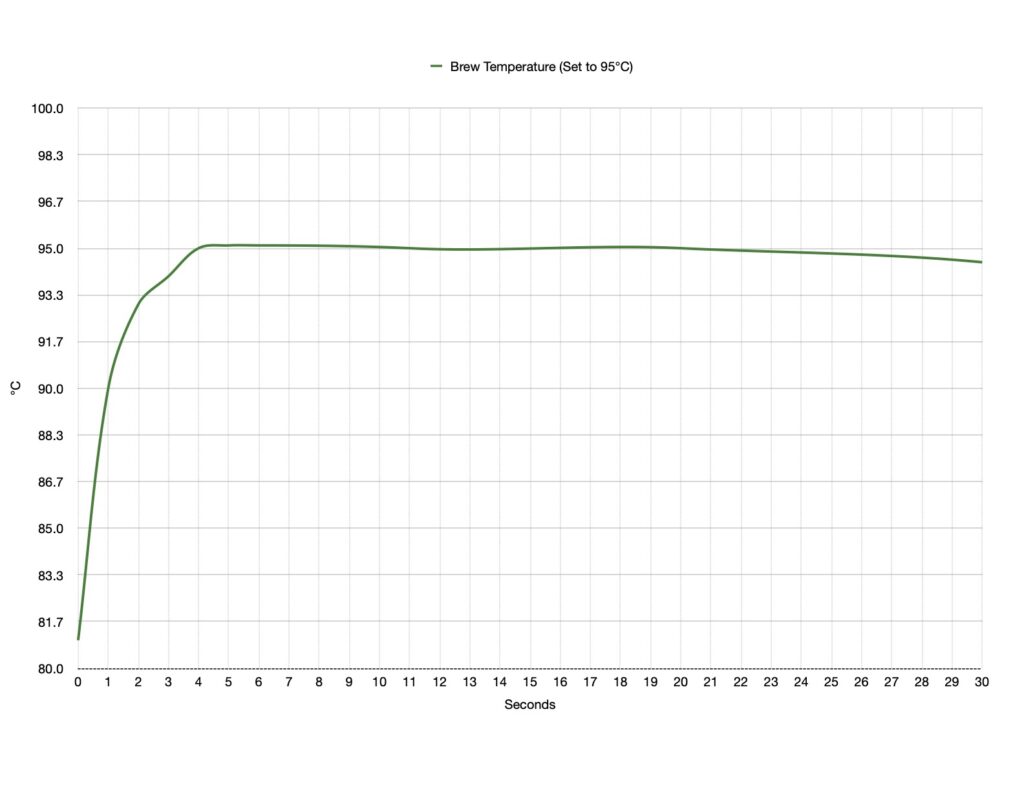

If the machine is properly warmed up, the temperature stays within +/- 1°C for the whole duration of a standard double-shot. This has been measured many times by Auber with a Scace Thermofilter, the PID definitely does a great job. I’ll include Auber’s statement in regards to this bellow.

The temperature change during the 25 second period is less than 2°C normally. It should be noted that because the peak value is used, the data we obtained will be higher than some other studies that used the average value.

The Correlation between PID Temperature Setting and Water Introduction – Brewing Temperature – By Auber Instruments April 2011

What i see on the controller during the extraction (indicating a temperature drop) does not matter all that much. The drop in the temperature on the controller doesn’t necessarily represent a temperature drop at the grouphead. The RTD temperature sensor is located at the top of the boiler, where also colder water is being pumped from – which means the drop in temperature displayed on the screen is completely normal and expected. The grouphead does a great job at keeping the water hot and at a stable temperature. The PID also starts heating the water in the boiler during the extraction in order to avoid a significant temperature drop.

It was also really helpful to determine and adjust the offset (Atdu setting on the controller, menu 0089) between the set temperature and the water temperature (at the group). The controller comes set to 105°C as default, with a default offset setting of 10°C. Which would mean, that by default i should be having brew temperature 95°C at the grouphead if i keep the controller set to 105°C.

In my case for example, i found my offset to be 5°C.

This means if i have 105°C set on the controller, the water at the grouphead is coming out at 100°C. I’ve changed the default offset (Atdu) from 10°C to 5°C.

There’s also another setting on the controller – PSb. Adjusting this parameter (located in menu 0089) allows me to adjust the display to show 5°C less (by setting it to -005) , which will result in seeing 100°C on the controller instead of 105°C.

Now that my controller is showing the actual brew temperature, i can go ahead from here and adjust my temperature for the coffee i’m currently using (95°C, works great for light-medium roasted coffee).

I’ve concluded that once the machine has been properly warmed up (i suggest letting it warm up for at least 45 minutes), the brew temperature won’t drastically drop bellow the set temperature by more than 1°C unless i run 80-100ml of water through. This seems to be consistent with the above statement from Auber.

Knowing what temperature i’m brewing at is definitely worth it. I think it’s really helpful to know that i’m brewing at +/- 1 °C of desired temperature – as opposed to not knowing and guessing.

The mass of the grouphead attached directly to the bottom of the boiler keeps the water at a stable brewing temperature. After i’m done with my shot, the recovery to desired temperature takes just a little while and stops right at 95°C and stays there. The PID also learns over time how to manage the temperature, so the more you use it the more data it gathers and more effective it becomes.

But how does having a PID compare to a Silvia without one? Other than not having to temperature surf, the stock bimetal thermostat is nowhere near as accurate as the RTD sensor. Without the RTD sensor and PID, i don’t really know if the orange light turned off at 90°C or 93°C, or even beyond that point on some older machines (even though it’s designed to turn off at 90°C). If the orange light correctly turns off at – let’s say precisely 90°C, i definitely have to start brewing right after the orange light turned off. And i still don’t know for sure if it really turned off at 90°C or 95°C. If i don’t start brewing right away, the temperature in the boiler continues to rise as the heating element remains hot. Some 5 seconds after the light turned off, the brewing temperature is at ~100°C+ and i’d have to temperature surf. Also, without the PID and with a stock bimetal thermostat, the heating does not begin in time and the drop in temperature of the boiler is far more extreme. The factory setting for the bimetal thermostat is limited to one parameter, which means it starts heating only once the bimetal strip detects a certain drop to a certain temperature. The PID is more intelligent than that and learns when to initiate heating in order to be as effective as possible and still not overshoot a set temperature. It sends pulses to the heating element, so that the temperature doesn’t overshoot beyond let’s say 95°C (my set temperature). I can set an exact temperature and the boiler temperature will stabilise and remain stable for as long as i’d like to keep the machine on. And as i start brewing, the heating element turns on when the PID decides based on an algorithm, not based on a bimetal strip that opens or closes.

The Rancilio Silvia with PID currently sells for around $1,099 (~910€). A stock Rancilio Silvia goes for around $735.00 (~605€) and the PID kit from Auber costs $159.50 (~130€). Installing the PID yourself will save you money, gives you a satisfying feeling of accomplishment and gives your Silvia some additional value. If you’re buying a Rancilio Silvia with PID preinstalled, you’re getting closer to a price range of machines with superior brew temp. control, such as the Silvia Pro. The Silvia Pro costs ~1450€ in Europe and is a dual boiler with dual PIDs. The machine’s temperature stability is superior to most machines used in WBC competitions and also proved to be capable of scoring remarkably in WBC benchmark tests. You can find more on that here:

https://www.silviaprousa.com/blog-archive/thermal-stability

I’m also very happy with the temperature-only kit. I think the kit with pre-infusion/steam is unnecessary, as the pre-infusion does nothing more than turning on/off the brew switch. For steam, if i start steaming soon enough, i’ll have enough steam power for the whole steaming cycle. The only additional feature the pre-infusion/steam kit has is an addition of a shot timer, which would be nice – but is also not super necessary. Plus, with the temperature-only kit, i get to use the brew switch just as you normally would.

To conclude this – it was totally worth it. If you’re seeking to perfect your espresso, PID is a way to go.

Let me know if you have any questions, i’d be more than happy to answer them!

Jaroslav

I am not affiliated, associated, authorised, endorsed by, or in any way officially connected with Rancilio, Auber or any of their subsidiaries.

February 25, 2021

That’s some source of knowledge about PID, thanks for making it approachable. 😊

February 25, 2021

Thank you! ❤️

April 13, 2025

good evening I just installed a PID kit without pre-infusion on the Rancilio Silvia V5, I started playing with the parameters and I made a bit of a mess, could you tell me the parameters that I have to adjust on the codes 00001, 00036 and 00089?

March 31, 2021

Interesting article! I didn’t know you could use menu 0089 to adjust the display temperature to account for the offset.

I was confused at first when I saw the “low” temperature on your PID in your videos. But after accounting for your offset, I found out we have exactly the same (boiler) temperature (103C) 🙂

March 31, 2021

Hi Maxim,

thanks for reading and leaving a comment! There are also many more menus that are hidden behind the numbers. There used to be a menu 0037, which would enable a shot timer on the standard controller (the one without Steam/Pre-infusion). The number has changed and it needs to be found!

Jaroslav

April 5, 2024

Hey Jaroslav,

Was the shot timer function ever found, this would save me from doing an extra mod

Also do you know if this was only available on Aubers PID, or if an XMT-7100 direct from china would also have this function?

Thanks Again

May 31, 2024

Hi Vig,

Not to my knowledge, no. Please let me know if you happen to find out, we can add it to the article for future readers.

Jaroslav

April 23, 2021

Hello, how did you test the temperature of the brew head ? I’m curious

April 23, 2021

Hi Jon,

thank your for asking! I’ve used a thermocouple. If you don’t have access to one of those (or can’t buy or rent one), let the machine warm up for 45 minutes and try setting the PID to a temperature where you know the water will spit steam when you hit the brew switch. Then drop by one degree at a time until water doesn’t come out bubbling out of the grouphead. If you’re seeing steam or hear hissing/bubbling at 105, but not at 104, then 104 on the controller should be 99°C at the grouphead (may depend on your elevation). It’s very important to let the temperature stabilize for a few minutes every time you make an adjustment and drop a degree.

I hope that helps!

Jaroslav

January 5, 2025

Could I ask how exactly you used the thermocouple? Did you just put the wire over the portafilter and into the basket before screwing it on to the machine? With or without coffee? Thanks for the advice 😀

January 5, 2025

Hi Cyrus,

If I remember correctly, I drilled a small hole in a single basket for the wire, packed the basket with coffee and made sure the wire sticks out above the puck. That’s probably as close as you can get to an accurate reading without the actual Scace basket.

Jaroslav

June 2, 2021

Hello! I bought a second hand PID Rancilio Silvia. The Auber PID reads in Fahrenheit, which does not work me. I know that is possible to change to Celsius in code 0089, CorF, but last time I changed it the boiler overheated and I had to reset the thermostat safety button. I noticed thar your machine is set to Celsius. Could you share your parameters Su, AH1 and AHL1 for code 0001? Also, if you coud share your parameters for codes 0089 and 0036, that would be great! Thanks a lot! A fellow coffee enthusiast from Brazil.

June 2, 2021

Hi Eduardo, try setting the SV bellow room temperature (let’s say 50°F) before performing the change. Then, in the menu 0089, change the Corf value from 1 to 0. The 1 is for °F and 0 stands for °C. After that, (in menu 0001) set SV to 105, AH1 to 175, AL1 to 160 – these are the default settings. Both AH2 and AL2 are would be set to 300 as default. I hope that helps!

August 20, 2021

Hi mate, it’s me again, hope you are doing we.

After changed the manual switch I decided to get the PID and it just arrived today.

Could I ask you if there’s any special steps need to be followed when installing the Auber PID with manual switch on Silvia E? The additional doc provided by Auber says the brew switch will replace the power switch, though I believe you managed to keep using the power switch. Were there any special steps you followed to achieve that? Thanks in advance.

August 20, 2021

Hi Julian,

thanks for asking! Would you mind telling me if you got the temperature only or the steam/pre-infusion kit?

Thanks

August 20, 2021

Sure. I got the temperature only one same as yours. I deliberately got it since I read your article and knew the preinfusion one will disable the brew switch.

August 20, 2021

Well done!

In that case no special steps are needed, just follow the steps from the named Silvia E note for RSRTDNb.pdf. Only the steam/pre-infusion kit has a slightly different wiring and requires the brew switch to be in the On position all the time. The “temperature only” kit let’s you use the brew switch as per usual.

If you don’t have the file I could send it to you.

August 20, 2021

Cheers mate!

I think you meant the 3 pages additional note file. If that’s the one then I have it.

Meanwhile I bought the black box one, seems to be a new option available recently. Will send you a picture once I installed it. Thanks for your kind help.

August 20, 2021

Anytime! Yes, that’s the one. I saw that! I was actually trying to get a black box from them back in January. They kept on delaying it, telling me to wait until March – now I see why. It’s a nice option, I’d say it will look much better.

Yes please, let me know!

Thanks

October 21, 2021

Great information!

Have established my offset and now my PID is also showing the “actual” temperature by lowering the showed number.

Thanks a lot!

October 21, 2021

Hi Bart,

no problem! I’m glad you found the article helpful and managed to calibrate your controller.

Thanks for the comment!

Jaroslav

December 28, 2021

thx very much for the info bro!

just installed the auber pid on my v6 yesterday and i also had an offset about 5 degrees celcius…

December 28, 2021

i did also set the Atdu value to 5 and Psb to -005.

too bad the display still shows 100 degree and not 95!

do you have a solution?

thx

December 28, 2021

You’re very welcome Tobias, congratulations on your achievement.

The controller comes set to 105 as standard (with default offset of 10). That’s why you’re seeing 100 on the display after changing the default value, this however doesn’t automatically include your newly set temperature offset.

Given your settings are correct, you can assume that the value on the display is now showing the temperature at the grouphead. You can therefore set it to 95.

I hope that helps!

Jaroslav

December 29, 2021

Can you please post your email address? Dont want to explode your commentsection!

thx

tobias

December 29, 2021

Hi Tobias,

Please use the comment section, someone else might find it useful.

Thanks!

December 30, 2021

Ok, lets recap, i have 3 variables:

1) Atdu (which is set to 10 from factory)

2) Psb (wich is set to 0 from factory)

3) SV (which is set to 105 from factory)

My offset tends to be 5, NOT 10, as measured the way you describe above.

So what I want is 95 degree at the GROUPHEAD AND 95 degree shown in the display.

First step was to set the SV Value to 100 (which means 95 degree at the grouphead because of my 5 degree offset).

Second step was to adjust the Atdu/Psb values to show 95 degree in the display.

My problem is, adjusting the Atdu/Psb values wont change anything… I changedd Atdu to 5 instead of 10 and Psb to -005 but it still shows 100 in the display (the same as my SV value)…

December 30, 2021

Firstly, you correctly found your 100°C at the grouphead. You’re seeing 100 on the display, which is also correct. The goal was to find the point at which you’re getting 100°C at the grouphead and 100 on the display – which is what you did correctly. You aren’t trying to achieve automatically having 95 on the display by simply changing the parameters, you’re trying to find a point at which 100 on the display reflects 100°C on the grouphead.

Based on what you described you did was first set the temperature to 100, then adjust the offset and Psb. It isn’t wrong, but skipping steps confused you.

Let me explain again – The controller comes set to 105 and 10 as offset. This means the controller assumes 95 at the grouphead with default settings.

Start again by setting all values back to default, beginning with Atdu and Psb, then SV – do it in this order. Now you have 105 on display, 10 as offset and Psb as 0 – the controller assumes 95°C at the grouphead. First change the offset (Atdu) from 10 to 5, the controller now assumes 100 at the grouphead while still showing 105 on the display – simple.

Second step is to change Psb to show 5 degrees less, you will see 100 instead of 105.

You’re obviously not going to brew at 100°C, so the third step is to choose the SV you want to brew at.

Seeing 100 on the display correctly reflects your settings. You want your controller to correctly assume 100°C at the grouphead while showing 100 on the display. First you’re looking for 100 on the display and 100°C at the grouphead, second step is to set the temperature you want to brew at.

Assuming you did everything correctly, you’re seeing 100 on the display after changing all settings, this means the 100°C at the grouphead are already reflected on the display.

As the very last step you’re going to set the temperature at the display to whatever you want to brew at (change the value from 100 to let’s say 95) and you’re done.

As a bonus step you can flush the grouphead and have some cold water in the boiler, let the controller stabilize the temperature on the set value.

I hope that helps!

December 31, 2021

hey bro, i followed your steps and it finally worked!

it seems i changed up the order…

anyways, before i asked you i wrote auber an email, here´s their reply to your routine:

The parameter Atdu only works when the controller runs auto-tuning. It doesn’t affect the displayed temperature reading or the target temperature (SV) at all.

Assuming you have all parameters at default in the beginning and the controller has brought the temperature to the SV, which is 105°C. See the default values in the link below.

https://xxx

If you change the PSb from “0” to “-10” and immediately exit to the main interface, then the displayed temperature should become “95” at that moment. But after a while, the controller will bring the temperature from “95” to “105” again. However, because of the “-10” offset, the actual temperature detected by the sensor at the boiler would be 115°C. Of course, then you can change SV from 105C to 95°C. Then the controller will keep the temperature at “95”. However, when the controller shows “95”, it means the actual sensor reading on the boiler is 105°C.

I also attached a temperature study we have done in the past on older models of Rancilio Silvia. Hope that helps.

Best regards,

January 3, 2022

Jaroslav, what do you think about the mail from Auber?

Thx

January 3, 2022

Hi Tobias,

I’m glad to see it had worked out for you! The reply adds another layer to the explanation. I hope you found it helpful, as hopefully someone else will too in the future.

Happy new year and good luck!

Jaroslav

January 3, 2022

what do you think about the email they wrote? if i get it right they explain it a bit different

January 3, 2022

Is there anything in particullar you see as being explained differently? Apart from merely explaining what effect changing these values has individually, there isn’t much more to learn from their reply.

January 3, 2022

The term “auto-tuning” confused me… Dont know anything about it

January 4, 2022

While auto tuning the controller is looking for optimal P, I and D values for better efficiency. You’ll find more on that in Auber’s documentation or through Google.

January 4, 2022

Auber wrote in their reply the Parameter Atdu only works in autotuning but in your tutorial its mentioned to be changed… But we arent working in auto all the time?! Still confused

January 4, 2022

Calling this a tutorial is a bit of a stretch, but thank you!

I’d suggest to ask the correspondent to elaborate. I used to run auto tune manually whenever I adjusted parameters or whenever ambient temperature changed with season. It’s true however that changing Atdu doesn’t affect the displayed temperature reading, but based on their documentation alone it definitely does affect the target temperature as it allows the controller to overshoot the set temperature by a given value.

From SYL-1512A instruction 2.3 :

Based on this, and based on what I was told and the way it was explained to me at the time, this value should reflect the offset and should be adjusted accordingly.

Hope that helps!

January 7, 2022

So Jaroslav, I did some testing with default settings (calculated with an offset of 5 degree) and also with your tutorial. I tried different temperature settings and it seems the result is the same.

Thx again for your blogpost!

btw, i also installed a wifi socket and stuck a tiny piece of anti slip mat into the powerswitch, it works great!

The only downside is the shower screen… i tried 2 different IMS and one from E&B labs but they wont fit.

I talked to E&B and theyre now producing a screen with a slighty larger diameter which should be ready in a few months.

Keep up the good work!

January 8, 2022

Hi Tobias,

Thanks for letting me know, anytime! Good luck with the Silvia. Some people did indeed report that their IMS-produced shower screen doesn’t fit the Silvia. I haven’t had such experience, it fit perfectly on mine.

Good luck with the machine and thanks again for the kind words!

Jaroslav

May 8, 2022

Hi Jaroslav!

So I’ve recently bought an PiD for my Rancilio V6 model. I am really happy for that!

Currently I am trying to find my offset, which I do find a bit difficult. So I have started to calculate it by setting the controller to 110 celcius and then slowly go downwards. The thing I am frustrated about is: When is there no steam from the group head? What am I supposed to look after? I do think that it looks much the same?

Can you help me out?

May 8, 2022

Hi Christian,

You should be looking for a setting at which the stream of water coming from the grouphead is without gurgling or bubbling. It’s very important to let the temperature stabilize for a few minutes everytime you adjust the controller by a degree. Here are few more resources you may find helpful:

A video demonstrating what you’re looking for:

https://youtu.be/k1b7TEJ18bo

A detailed explanation for this method:

https://www.home-barista.com/espresso-machines/pid-d-rancilio-silvia-owners-what-temperature-do-you-run-t10767.html#p122988

I hope this helps and good luck!

Jaroslav

May 8, 2022

Hi again!

So I’ve watched that video a couple of times, but to me the different temperatures looks the same. Can you tell me why the 103 celcius is more “correct” than the 105 celcius? The amount of steam in the air around the GH and bubbles looks much the same?

September 25, 2023

Hi!

I have found that this method has some limitations – This helps find the offset against no resistance, but if the water finds a resistance (e.g. a coffee puck) then the offset changes quite significantly; this is why a scace is so handy.

So I built a home made scace (inserted a thermocouple probe into a basket through a drilled hole, filled the basket with epoxy, and let a hole that could be controlled with a needle valve to be able to control the resistance pressure).

Doing the above, I found an offset of 7C on average on my Silvia. The linked youtube video is of my machine actually -then it was insulated, and now it is not because I found it cooled down more quickly without which sometimes was handy.

I will try to reproduce the experiment in the video now that the machine is non insulated see if anything changes…

September 25, 2023

Hi Alberto, thanks for stopping by!

Regarding the DIY scace – well done, and you’re absolutely right. You’re welcome to post links to your experiments here (if you decide to make another video), I’m sure future readers will find it useful.

Jaroslav

May 8, 2022

Also regarding the bubbles: when I look at 103 and 102 celcius in the video, I seem to see just as many bubbles when the water is 102 celcius? I am so confused haha 🙂

May 9, 2022

Hi!

It’s okay to be confused while it’s new to you. You can hear it gurgling at both 105 and 103 in the video, it only stops gurgling as the temperature is set to 102. Which would mean 103 on the controller is still boiling water coming from the grouphead, but not at 102. Have a read in the description bellow the video as well.

Take care!

Jaroslav

December 23, 2022

Hi Jaroslav,

Thank you for the detailed guide.

Installed my own Xmt7100 Pid last week and have been enjoying the machine since.

My parameters are identical to that outlined in the guide however one issue I’m running into is that after pulling a shot, the boiler overshoots by about 5 degrees C and then settles down to the temp set in Su. Any idea on how I can prevent this overshoot? Thanks

December 23, 2022

Hi Vig,

Congrats to your installation. I’ve never had this issue with Auber’s kit, but given how PIDs work it’ll be a matter or adjusting (increasing) the D and I values until it stops overshooting.

Jaroslav

April 5, 2024

Hey Jaroslav,

Thanks for your response.

I tried increasing both I and d values but it didn’t seem to solve the issue. Do you have any suggestions on how to adjust these values?

Could you also please give your inputs for the following (I know some are outlined above but it might be helpful to have all PID inputs shown in one place):

Code: 0001

SU

AH1

AL1

Code 0089:

Inty

Outy

Rd

CorF

Hy

Code:0036

P

I

D

May 31, 2024

Hi Vig,

Sorry for the very late reply, I didn’t get notified of your comment for some reason.

Try to look for Auber’s documentation or contact them for all the default values. I’m not sure if you’re aware, but I haven’t owned a Silvia since mid-2021, I can’t remember what the values were. Sorry!

Jaroslav

September 30, 2023

Great post. Thanks for taking the time to write this. Out of interest, what level of elevation were you at at the time or writing? Thanks

November 3, 2023

Hi,

I also bought the PID without preinfusion but I haven’t yet installed it. Any of the videos I have seen of installation online seem to be for the other model with preinfusion and the instructions on the Auber kit seem to be different to those in the videos. Can I ask you please, where did you mount the SSR on the machine? The Auber instructions say to install it on the wall behind the splash guard panel however, any videos I’ve seen online say to mount it to the frame of the machine at the back. Where did you mount your one?

Thanks.

November 3, 2023

Hi Ronan,

I installed mine behind the splash screen. I highly recommend to follow Auber’s manual rather than watching videos. Their step-by-step guide is all you need.

Jaroslav

November 12, 2023

Just wanted to thank you for your reply. I went ahead and installed it using the instructions and it was better than I expected. Still quite tricky but it’s definitely worth taking your time to go through the steps. It’s made a great improvement to the machine though. Thanks again!

February 6, 2025

Hi. I have an XMT7100 and not the Auber and hence don’t have the atdu setting. If I want 95 at group head and assume that setting temp at 103 will reach that, am I supposed to set psb to -8 to get the correct temp displaying? Or will it then increase temp further? Thanks!